3 layer coextrusion, equipped with traction rotation haul off, IBC, automatic winder, computer centralized system

3 layer co-extrusion film blowing machine is used for blowing with HDPE, LDPE and LLDPE materials to blow the special film which is widely used in the liquid film, pearl film, composite-based film, heat shrinkable film, tire separation membrane, anti-aging multi-functional film, anti-jamming membrane, impermeable film, stretch film, cable film, etc.

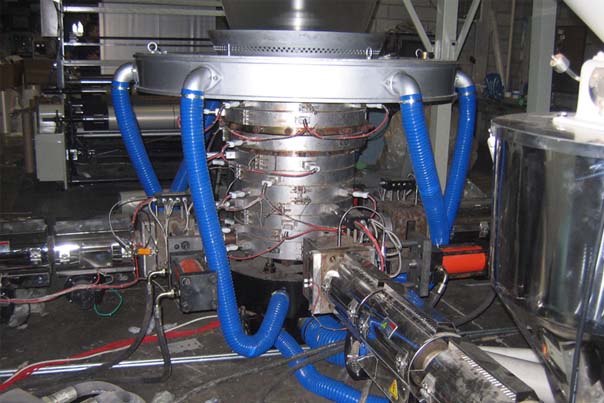

Mandrel spiral die head made by CNC Machining Center with mirror polishing

High-quality alloy steel screw and barrel, nitrited, best hardness and corrosion resistance

IBC (Internal Bubble Cooling) system

360° horizontal traction rotation haul-off system

EPC device by photoelectric control

Auto tension control system

High-Speed screen changer with melt pressure gauge

Automatic winding system by PLC computer control

Machine is full automatically controlled by centralized computer system

Siemens Brand inverter and Siemens serial related products control system

Model | SJ-50x3/28-BL1400 | SJ-50x3/28-BL1600 |

Co-extrusion Layers | 3 Layers | 3 Layers |

Suitable Material | LDPE, LLDPE, mLLDPE | |

Max. Folding Film Width | ||

Film Thickness | 0.04 | 0.04 |

Max. Output | 180hr/hr | |

Screw Diameter | φ50x3 | φ50x3 |

Screw Ratio(L/D) | 28:1 | 28:1 |

Max. Screw Speed | 120r/min | |

Main Extruder Motor | 22KWx3 | 22KWx3 |

Die Sze | φ250-350 | φ250-350 |

Mode of Bubble Cooling | Dual Lip Air Ring IBC (Internal Bubble Cooling) | Dual Lip Air Ring IBC (Internal Bubble Cooling) |

Mode of Reversing | 360o horizontal reversing haul-off | 360o horizontal reversing haul-off |

Width of Auxiliary Machine | ||

Winding Mode | Back-to-Back Two Station Double Winder | |

Max. Winding Diameter | φ600 | |

3 layer coextrusion main extruder

3 layer IBC system

Traction rotation haul off system

Automatic double winder

3 layer coextrusion machine

E-CATALOGUE, PRODUCTS PROMOTION AND NEW

TEL: 0086-137-5771-8535

EMAIL: sales@polyextruder.com

ADDR: Daji Industrial Zone,Caidian District,Wuhan City,Hubei Province,China